BASICS OF PLATING

“Plating” is a well known term. But what exactly is “Plating”? We explain below the basics of what is known as electroplating.

The Word “mekki” (plating)

In Japan, the development of plating technology can be traced back to the Nara era. The Nara Buddha Statue was coated with mercury and gold alloy and upon heating the mercury would evaporate, leaving a thing coat of gold on the surface.

This original method of gold plating was called “mekkin” which in turn became the word “mekki” which is used to this day.

IRIDEN’s focus is on electroplating

There are three main categories of plating methods

- Wet plating

- Dry plating

- Hot dipping

IRIDEN focuses on wet plating, in particular electroplating.

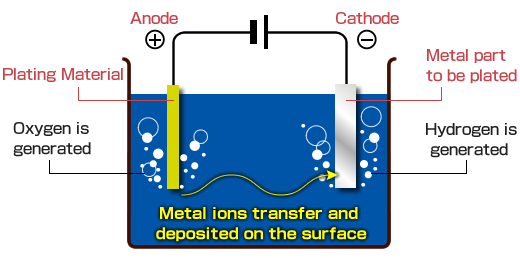

The electroplating process

The basic process for electroplating is as follows; the plating material and the metal part to be plated are both immersed in a solution. An electrical current is supplied so that the plating material becomes the anode (positively charged) and the metal part to be plated becomes the cathode (negatively charged).

The electrical current provides a positive charge to the plating material ions dissolved in the solution and these ions attach to the metal part to be plated. (This is called “deposition”)

The metal ions return to its original metal state at the cathode and form the plating.

By continuing the supply of the electrical current, the metal part is gradually plated. This is the basic process of electroplating.

IRIDEN’s “Revolving Plating”

As can be seen in the diagram above, it was typical for electroplating to be done by “hanging” the metal part to be plated within the solution. This is called “Rack Plating” and is still used today but has the following downsides;

- depending on the shape of the part, hydrogen bubbles can get trapped in an uneven surface and prevent proper plating

- it can be inefficient to “hang” large volumes of small parts such as accessories

- the use of hangers can leave marks on the parts resulting in inferior finishes

In order to prevent these problems, we adopted the “Revolving Plating” method from Germany for the first time in Japan.

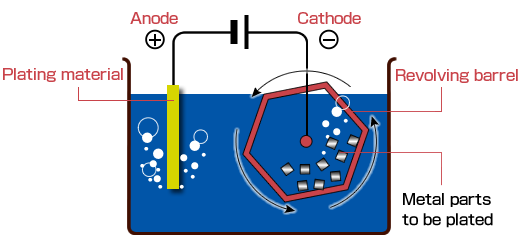

The basics of revolving plating

Revolving plating is a process whereby the parts to be plated are placed inside a perforated barrel which revolves while immersed in the solution. Since it uses a barrel the process is also known as barrel plating.

The below diagram shows the basic setup for revolving plating.

This diagram is quite simplified but shows the fundamental process of electroplating remains the same.

The parts to be plated are placed inside a revolving barrel which is connected to the cathode and an electrical current is supplied. The electrical current is conducted via the revolving barrel and the parts within become plated.

The benefit of barrel plating is that parts that are difficult to hang such as small screws and rod/tube shaped parts can be treated in large volumes. It is also easier to achieve a uniform layer of plating.

IRIDEN continues its efforts to improve on its technology

Since the parts rotate inside the barrel, revolving plating is not ideal for parts such as springs that tend to get caught inside the barrel. However we have accumulated our technologies over the years to gradually overcome this weakness.

Also, it is very important to properly pre-treat the parts through processes such as degreasing and acid treatment. For example, any fingerprints left on the parts will result in an inferior finish. Grease is typically removed by an alkaline solution but some metals will dissolve when exposed to an alkaline solution with high ph so an appropriate method needs to be devised.

We believe it is under these situations that our know-how will result in a superior outcome for our customers and that is why we continue to adopt new techniques and continue our efforts to enhance our technologies.